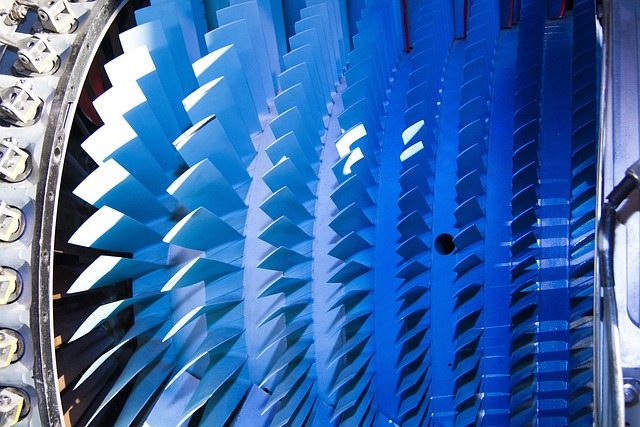

A turbomolecular pump is similar to a turbo pump and is used to maintain a high vacuum by drawing air molecules from the element. In these pumps, the rotor directs the gas molecules from the inlet to the exhaust, leaving a vacuum. Turbo pumps play several significant roles in aircraft.

Where Can You Find Turbomolecular Pumps?

These pumps are readily available even on a small-scale level. To compare prices and specifications or even make purchases, provac.com is one of the best and most resourceful sites. It has variety and even offers advice to clients.

Powering Gyroscope Instruments

Gyroscopic instruments are flight instruments with mechanical gyroscopes integrated into the design. These instruments consist of three main types on an aircraft: the heading indicator, the artificial horizon, and the turn coordinator. They use gyroscopic axes as a starting point for measuring aircraft orientation.

Understanding Gyroscopic Instruments

In simpler terms, a gyroscope is a while that is constantly spinning on an axis. In its spinning motion while in an inertia state, the gyroscope develops a concept known as rigidity in space. This generally means that the axis will point in the same direction for as long as it remains unmoved.

A typical gyroscope instrument will have three main integral parts: An axis with a single gyroscopic axis with the spin axes, the input and output axes. Another part is the wheel which, in its spinning nature, fulfills the concept of rigidity. The last part holds the axis and the wheel together, and it is referred to as the gyroscope gimbal.

Powering the Gyroscopic Rotor

The gyroscope’s spinning nature is essential in maintaining the rigidity effect. In small and mid-size aircraft, suction is used to power the rotor. Gyroscopic instruments will typically be powered either electrically or pneumatically. Turbo pumps powered by the engine will be used within the motor to create negative pressure.

Air from the cabin is drawn and filtered into the component. It is then directed to the gyroscope wheel, causing it to turn. The pressure, however, needs to be maintained; if it drops, it could cause under-reading. This concept works for low-altitude aircraft.

Gyroscopic instruments are essential in helping an aircraft gain orientation and maintain angular velocity. They essentially act like the plane’s navigator; without them, the aircraft would lose direction, which would be catastrophic. Turbo pumps are, therefore, essential in powering these components and are vital in sustaining the travel industry.

Food Preservation

Another key role turbo pumps play in air travel is food preservation. Statistics have shown that around 500,000 people are on board an aircraft at any given time. This translates to more than 4.5 billion scheduled passengers per year, which is quite a large number.

When dealing with such a large number of travelers, feeding them becomes an issue that should be addressed before the journey starts. Moreover, with the aircraft scheduled to make as many trips as possible, providing fresh from the kitchen food made from scratch is not easy. Food is typically not prepared mid-flight but is cooked on the ground and transferred to the plane for refrigeration, where the attendants will heat and serve it.

This food needs to be well stored for efficiency, so it does not go bad before consumption. Some of it may also end up not being consumed, and if it is not correctly preserved could be termed as waste. This is where the vacuum concept of turbo pumps comes into play.

When the food and items are transferred to the aircraft for storage, some of them are vacuum-sealed to ensure longevity. This involves sucking the air molecules from the food to leave behind an anaerobic environment, which, when subjected to freezing, leaves no chance of bacterial or pathogen growth within the food item.

This is how foods are guaranteed longevity, especially in fast-moving aircraft. These turbo molecular pumps also maintain a sterile environment during the processing and transportation of food. In storage also, the pumps are used to maintain a vacuum environment that hinders conditions for the growth or multiplication of harmful pathogens.

Packaging of Export Products

This is yet another vital role played by turbo molecular pumps. When dealing with high-value and potentially perishable export cargo, anything can go wrong and cause the involved participants to suffer massive losses. For this reason, a lot of care is taken during the production of packaging materials.

The materials are typically produced in a system that uses a vacuum for two main reasons, one of which is sterilization. This ensures that when dealing with sensitive freight such as food substances, there is minimal possibility of it getting contaminated. The other reason is that the vacuum pumps can quickly identify potential problems in the system before anything goes too far to cause future problems.

Therefore, turbo molecular pumps play an integral role in the growth and development of the industry by ensuring the most important aspects of air travel are well addressed.